Guidelines on Post-season Maintenance of Balers

Proper maintenance of balers after the operating season is essential for extending their service life and improving efficiency for the next season’s operation. This article outlines the key aspects of post-season maintenance for balers.

Preparation Before Maintenance:

- Ensure the baler has completely stopped running and has cooled down. Cut off the power and fuel supply.

- Gather necessary maintenance tools such as wrenches, screwdrivers, brushes, and lubricants.

- Clean the debris and dust around the baler to provide a safe working environment for maintenance.

Maintenance of Main Components:

- Engine Maintenance:

a. Replace the engine oil and oil filter according to the baler’s oil specifications and replacement cycle.

b. Check the air filter; clean or replace the filter element to ensure proper airflow.

c. Inspect the spark plugs; replace them if there is significant wear or carbon build-up.

d. Check the tension of the belts and drive chains, adjusting them if necessary. - Hydraulic System Maintenance:

a. Drain the old hydraulic oil from the system, replace it with fresh oil, and clean the hydraulic tank.

b. Inspect hydraulic pipes and joints to prevent leaks.

c. Clean the hydraulic filter and replace the filter element as needed.

d. Check the condition of the hydraulic pump and motor; repair or replace them if there are unusual noises or vibrations.

3. Knotter Maintenance:

a. Clean dust and debris from the knotter, particularly around the knotting needle and cutting blade.

b. Inspect the knotting needle for wear; replace it if it is excessively worn.

c. Clean and lubricate the cutting blade for smooth operation.

d. Check the transmission components of the knotter, such as belts and chains; adjust or replace them if there is wear or looseness.

4. Hay Picker Maintenance:

a. Remove weeds, straw, and other debris from the forage picker to maintain normal operation.

b. Check the wear condition of the chains and sprockets; adjust or replace them if necessary.

c. Inspect the tooth plate and rod for wear or deformation; repair or replace them.

5. Additional Component Maintenance:

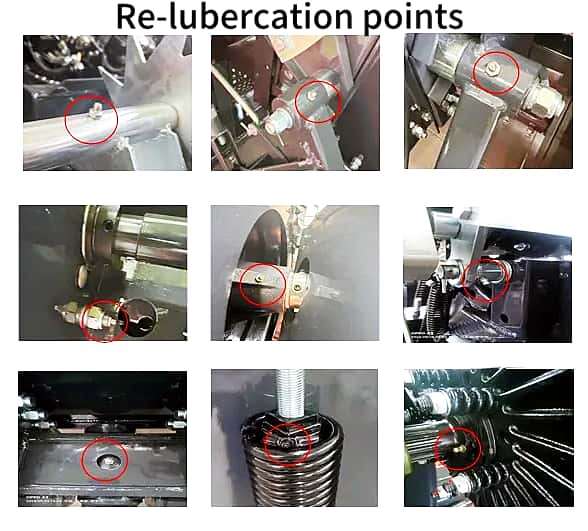

a. Clean and lubricate bearings and lubrication points of the baler to ensure proper lubrication.

b. Check tire pressure; inflate tires if they are insufficient.

c. Inspect the electrical system for damage to wires and plugs, ensuring there are no short circuits.

Inspection and Debugging After Maintenance:

- After completing maintenance, reinstall all components securely.

- Add an appropriate amount of fuel and lubricating oil, then check the lubrication status of each component.

- Start the baler and run it for a brief period to check the working conditions of the engine, hydraulic system, and knotter. If any abnormalities arise, stop the machine immediately for inspection and repair.

- Conduct a comprehensive debugging of the baler to ensure all parameters, such as knotting speed and forage picking efficiency, meet requirements.

Precautions:

- Follow appropriate safety procedures during maintenance, including wearing helmets, gloves, and other protective gear to ensure personal safety.

- Understand the structure and operating principles of the baler before starting maintenance to avoid damage from improper handling.

- When replacing parts, select high-quality original parts or equivalent substitutes to ensure reliable performance.

- Pay attention to environmental protection during maintenance to avoid pollution.

By adhering to these post-season maintenance guidelines, you can extend the service life of the baler and improve its operational efficiency, preparing it for the upcoming season.

This content is for reference purposes only. Feel free to adjust and supplement it based on your specific situation. For further questions about baler maintenance, it is advisable to consult Huaxi Tech’s professional agricultural machinery maintenance personnel or our after-sales service.